This is my first post of this kind, which I plan to use to give insights on how an electronic circuit is designed. In the future, I plan to post a similar article for every new circuit I design and present on my YouTube channel.

This way, people who are interested in such details can go to this site to get them, thus sparing all the others that don’t care from watching them on the original video.

Today, to get started with the new series of posts, I will go into the insights of the design of the Pitch Reference Oscillator used in the Theremin version 1.

I decided to use the Pitch Reference Oscillator because all the other Theremin’s oscillators are based on the same principle, although for the variable ones, an antenna is added to the resonant circuit to make its capacitance increase based on the position of the hand on the player with respect to the antenna. In fact, the antenna adds up to 8pF to the resonating tank, based on the position of the hand of the player.

For reference, you can watch any of the YouTube videos on my channel related to oscillators in the Theremin Project playlist.

Here is the link to the playlist:

https://www.youtube.com/watch?v=moT9iAaZU-I&list=PL3SNC7XyKklYZOs48Qfh16nTO4t8edDPU

I began the design of the oscillator starting from the base concept of positive feedback amplifier, which can be represented as follows:

We have an amplifier with a positive gain, which should be 1 when there is an oscillation, and we have a feedback impedance Zf that takes part of the output signal and brings it back to the input of the amplifier. Zf is supposed to be chosen to obtain a positive feedback at the oscillation frequency.

This basic configuration needs now to be modified to insert in it an LC resonating tank. This should be on the output of the amplifier, so its oscillations can be fed back to the input and be sustained with no decay.

The amplifier can now be replaced with a real circuit made with a transistor. I choose in this case a common base configuration, which gives me the required gain of almost 1, which is enough to sustain the oscillation.

The Zf will need to provide a phase shift of 90° to compensate for the internal capacitance of the transistor, which will add another 90° for a total of 180°, thus providing a positive feedback, considering that the transistor has actually a negative value of amplification (-1).

Therefore, Zf can be replaced with a simple capacitor that will bring the output signal back to the input with the desired 90° phase shift.

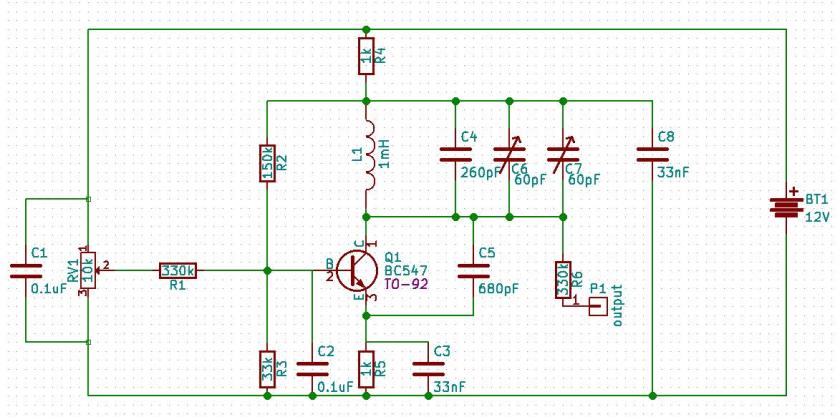

And once all the polarization resistors are added, the circuit looks like the following:

In this circuit, R2, R3, R4 and R5 are the polarization resistors, which are calculated based on the specs of the transistor itself.

L1, C4, C6, C7 constitute the resonating tank. The Two variable capacitors are added to allow for a fine tune of the frequency.

C5 is the feedback impedance, or Zf.

The resonating frequency is calculated based on the following formula:

where L = L1, and C = C4//C6//C7//CBE = C4 + C6 + C7 + CBE

and CBE is the capacitance between emitter and base.

Temporarily excluding CBE from the calculations, the frequency therefore can vary between 258.2 kHz and 312 kHz. The CBE can be obtained from the transistor data sheet, adjusting for the polarization between base and emitter.

Also, we can slightly affect the resonating frequency of the oscillator by changing the polarization point of the transistor. This can be achieved by a potentiometer added on the base of the transistor itself, as per the following schematic.

All the other capacitors in the schematic are used to make the polarization point of the transistor independent from the oscillation frequency, by shunting the oscillation signal toward ground. Thus, their value is such that they behave like conductors with respect to the high frequency of the oscillator.

At the end, considering the increase in capacity given by CBE, the frequency ends up to be centered around 400kHz, which was the required frequency for the pitch reference oscillator.

(This picture, courtesy of Wikipedia)

(This picture, courtesy of Wikipedia)